- Homepage

- PROFESSIONAL

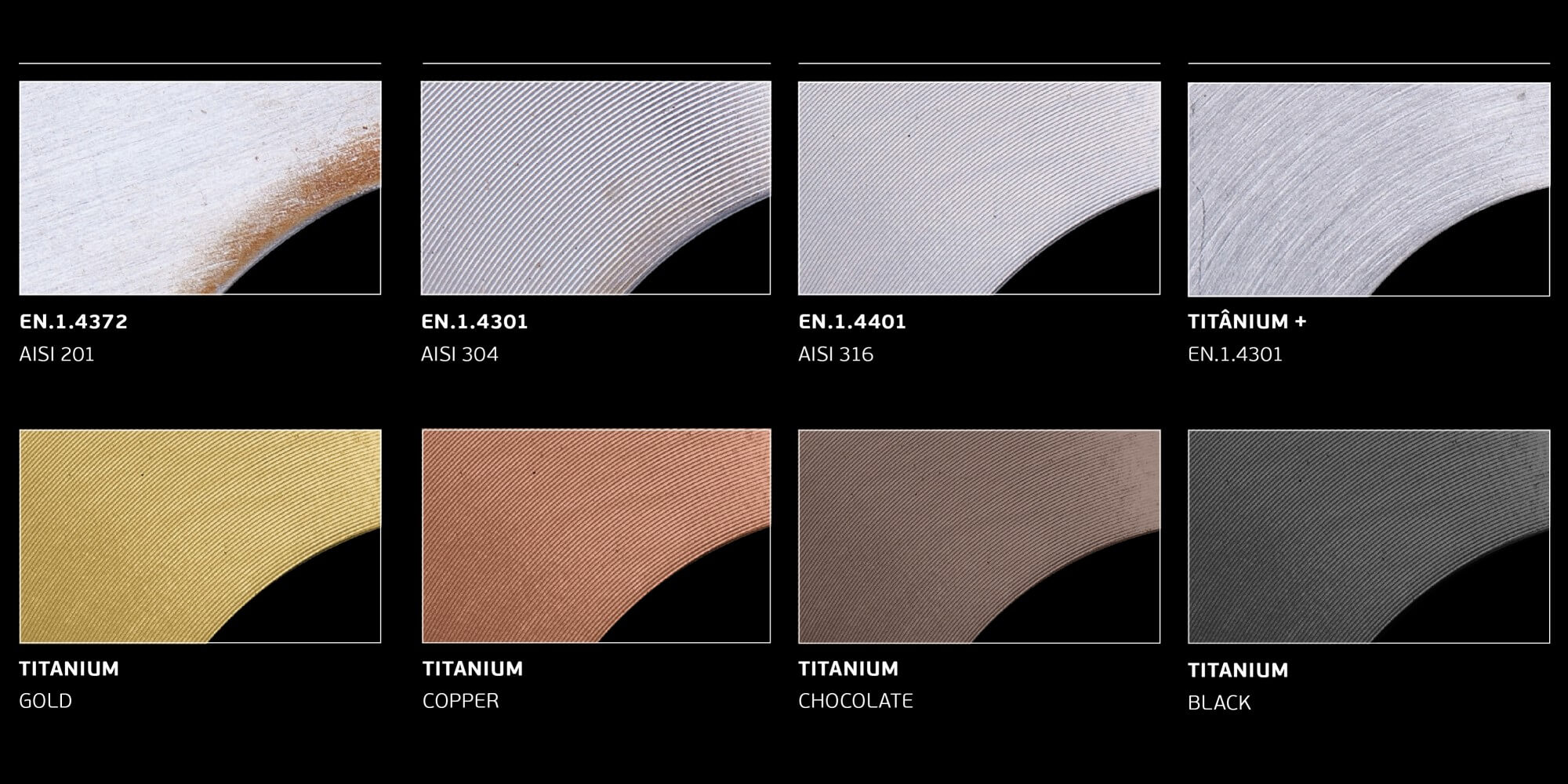

- MATERIAL GENERAL DATA

MATERIAL GENERAL DATA

REAL TEST OF CORROSION RESISTANCEThe test was performed according to test conditions NP EN ISO 9227:2011, method for testing and sorting according to standard EN 1670:2011 with 480h salt spray from a solution of sodium chloride to 5%. |

SATIN OR BRUSHED STAINLESS STEELThis is our standard finish. The steel is polished to achieve a "matt" finish with no shinning. Our matte finish is obtained with high quality materials, achieving a very low surface roughness but wich, however, remain non-glossy, functioning as "neutral" pieces, reflecting tenuously the surrounding tones. All our products are available with this finish. |

MIRROR POLISHED STAINLESS STEELSpecial finish on stainless steel. This finish results from the polishing of the steel until obtaining completely smooth and shiny surfaces. It’s similar to a bright chrome finish. The pieces reflect shinning surrounding tones. Some of our pieces are available at this finish. Generally, with few exceptions, all fittings can be manufactured in this finishing. There are limitations on the size of parts that can be mirror polished. |

INDUSTRIAL "RAW" STAINLESS STEELSpecial finish on stainless steel. This finish is achieved in the final phase of the polishing process. The parts are subjected to a treatment of abrasion. The end result is absolutely dull pieces with a very nice texture to be touch. Visually, the pieces have a grey "concrete" like color, giving the image of industrial parts, like they were tools. All our parts can be manufactured in this finish, however there is a limit on the maximum length of 600 mm. |

STAINLESS STEEL JET FINISHSpecial finish on stainless steel. This finish is achieved in the final phase of the polishing process. The parts are subjected to a treatment with projection of glass particles. The final result are pieces of uniform matte grey color with a nice texture to be touched. Visually, the pieces have a slight coloring, perfectly suited to environments where no metallic glare is desired. The resulting pieces are completely discreet and integrate in any type of decoration. All our parts can be manufactured in this finish, however there is a limit on the maximum length of 600mm. |

BRONZEBronze is one of the noblest metal alloys used by Man since the prehistoric period. The true bronze corresponds to a copper-tin alloy, having a high hardness, which gave him prominence in the manufacture of weapons for centuries. JNF developed a line of true bronze fittings made for some segments of architecture. The resulting pieces have a truly amazing charisma, giving a feeling of absolute timelessness. The various shades of bronze color, throughout their aging process are, by themself, captivating, since the coloring of copper to the green that we know from statues. A dedicated catalogue to this line of products is available by request. Another very important feature of bronze is its antibacterial and anti viral activity. There is no bacterial growth on bronze and cooper surfaces. In many bacteria specimens the cooper or bronze are bactericidal. |

SILVERWe had the courage to reconcile classical handmade jewelry with the latest technology used in creating this collection of handles. It’s a true collection of jewelry, handcrafted in 925 true silver with stainless steel machined in numerical control centers. The classic design is inspired in forms of traditional Portuguese jewelry. Manufacture is fully developed by the silver industry, each piece is certified and has the mark of authenticity showing the hallmark of "law silver". This is a line of handles for a very exclusive market sector. |

Product (s) added to cart